#Qwistle - The Printable Pennywhistle

£5.00

#Qwistle – The Printable Pennywhistle

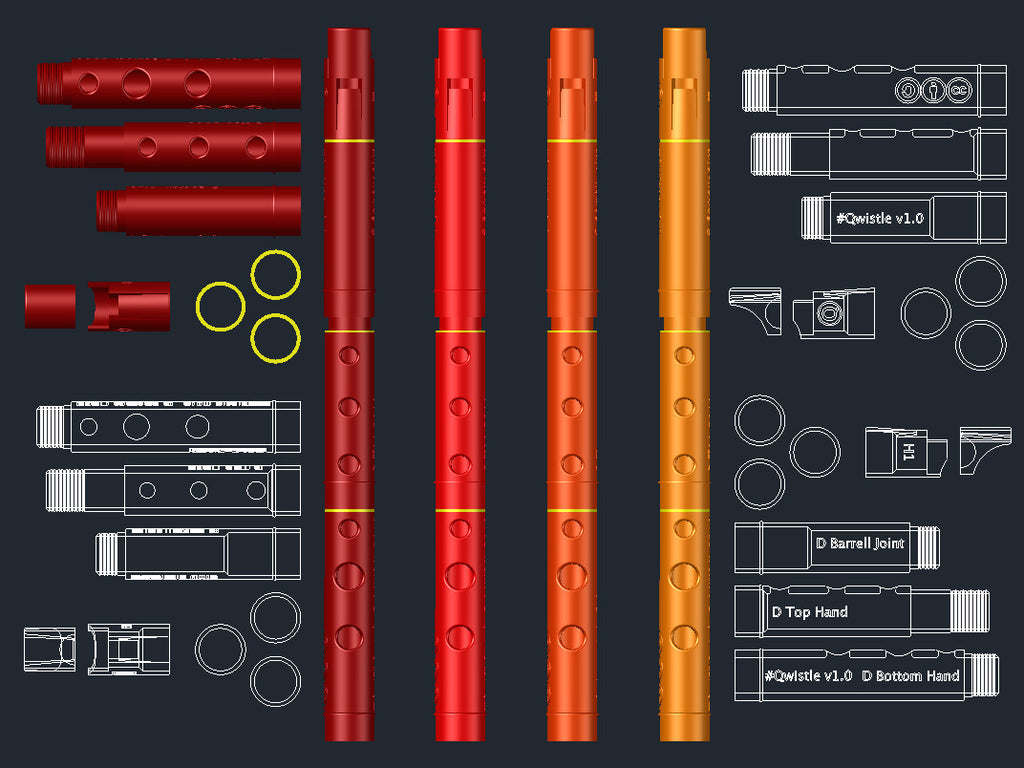

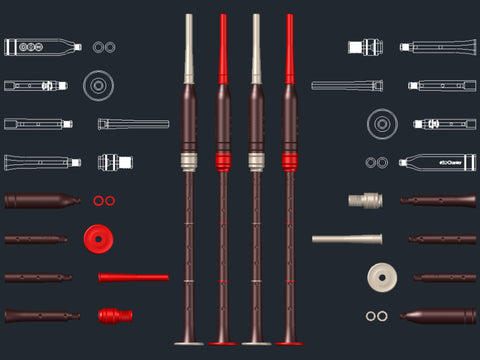

The #Qwistle is a 3D-printable soprano pennywhistle in D, designed for Irish, Scottish, Kwela, folk – or whatever you want to play on it.

On this page the Qwistle is offered in digital form for you to print at home on your own FFF printer. If you’d prefer a ready-made instrument, you can order a finished Qwistle from the main Lindstruments Qwistle page.

What the Qwistle File Kit is

The Qwistle File Kit provides all the STL files needed to print Qwistles on most home 3D printers. The set is optimised for FFF (Fused Filament Fabrication) printers and was originally developed with RepRap-type machines in mind. All component parts are restricted to a Z-height of 100 mm or less, and arranged so they can be printed without support, making the kit accessible to basic printers as well as more advanced machines.

Licence and sharing

The Qwistle File Set is offered under a CC-BY-SA Creative Commons licence.

You are free to print, share and sell Qwistles made from this set – at coffee mornings, car boot sales, sessions, wherever you like – provided you respect the licence (attribution and share-alike). I’m always interested to hear where the Qwistle ends up.

Print settings (summary)

(More detailed guidance is supplied in the ReadMe document included with the files.)

-

All parts should be printed at 100% infill.

-

For body sections, use 0.24 mm layers maximum.

-

For head sections, finer layers (around 0.12 mm or lower) greatly improve the functioning of the fipple.

Finishing and voicing

To get the best from your printed Qwistle, hand finishing is important:

-

Smooth the inside of the bore using rolled-up sandpaper of progressively finer grades.

-

Carefully smooth the inside of the windway, using small strips of sandpaper.

-

The blade (labium) and its ramp should be very carefully smoothed on both sides. Start with a rougher grade to remove visible layering, then work up to very fine paper (around 1200-grit wet-and-dry or finer, used with water/spit and elbow grease).

Time and care spent on the outside of a 100%-infill Qwistle can produce a surprisingly shiny surface finish. The embossed text will survive sanding well and can be inlaid with paint or other materials; just be aware that you may sand away the small decorative beads unless you’re careful (removing them is one option).

How you shape the windway and blade during sanding is the main factor in the sound your Qwistle produces. Printed parts should be treated as a starting point, not a final state: print multiple heads/fipples and experiment.

Further resources on voicing and tweaking

Here are some good starting points for understanding whistle voicing and tweaks that apply directly to the Qwistle:

-

Guido Gonzato’s “Low-Tech Whistle” making guide – general whistle-making and voicing.

-

“How to Tweak Plastic Mouthpiece / Cylindrical Shaft Whistles” – advice from Dale Wisely, Jerry Freeman & Joe Wilson on modifying plastic-mouthed whistles, very applicable to Qwistle tweaking.

-

Chiff and Fipple – a long-running online hub for whistle players and makers.

Customisation potential

Because the Qwistle is modular and 3D-printed, there is substantial scope for custom designs:

-

With STL files, a RepRap-style printer, fine sandpaper and some whistle-tweaking knowledge, it’s possible to produce a wide range of whistle sounds from the same base kit.

-

Players with CAD skills can adapt any part – mouthpiece, windway, body – to suit their own ideas.

The design has already been used to create Qwistle-derived instruments in various pitches, keys and bore sizes, including wide-bore Bb and A Qwistles with a more flute-like tone, a Qwistle customised specifically for the scale used in Alasdair Roberts’ song “Hurricane Brown” (performed at the Glad Cafe, Glasgow, in 2015), and a Qwistle-derived tabor pipe created by “Dreaming Pipes” backer Bill Owens.

Download

Files can be downloaded immediately after payment.

Share this item: